Title: The Manufacturing Process of Down Comforters

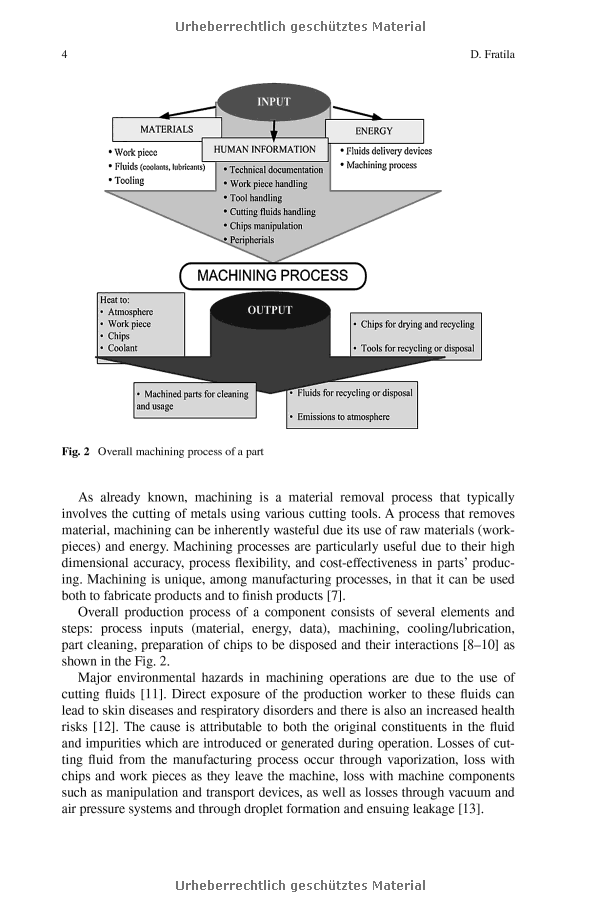

The manufacturing process of down comforters involves several steps, starting with the collection and cleaning of feathers from ducks or geese. The cleaned feathers are then sorted by size and quality. Next, they are decontaminated using various methods such as steam washing or chemical treatments to kill bacteria and dust mites.The cleaned feathers are then combined with filling materials such as synthetic fibers, cotton, or wool to create a layer that provides insulation and warmth. This layer is then wrapped around a shell made of soft fabric, such as polyester or nylon, which helps protect the feathers and fill material from wear and tear.Finally, the shell is attached to the filling material using various stitching techniques to create a complete comforter that can be washed and dried regularly. The end result is a comfortable and cozy down comforter that provides warmth and insulation in any weather condition.

The Manufacturing Process of Down Comforters

Down comforters have been a popular choice for bedding due to their exceptional warmth and comfort. This is because down is a natural insulation material that is produced by certain animals, primarily birds such as ducks, geese, and swans. The production of down comforters involves a complex process that requires skill, expertise, and attention to detail. This article will provide an overview of the manufacturing process of down comforters, from gathering the down to filling and stitching the cover.

The first step in the manufacturing process of down comforters is collecting the down. This is typically done when the birds are born and their feathers are still fluffy. The down is gathered by skilled workers who carefully remove the feathers from the bird's body while ensuring that as much of the bird's natural insulation as possible is preserved. Once the down has been collected, it is cleaned to remove any dirt, debris, or other impurities.

After cleaning, the down is sorted based on its weight and quality. The lighter and higher-quality down is usually more expensive, as it offers better insulation and warmth. Next, the down is carded or spun to separate the smaller feathers from the larger ones. This process helps to create a consistent fill that can be evenly distributed throughout the comforter.

Once the down has been carded or spun, it is ready to be filled into the comforter. This is where the cover is made. The cover is typically made from a variety of materials, including cotton, synthetic fibers, or a blend of both. The cover is designed to fit snugly over the down comforter, providing a protective layer and helping to keep the filling inside dry.

The next step in the manufacturing process of down comforters is filling the comforter with the down. This is typically done using a specialized machine that carefully spreads the down evenly across the cover. The filling is then sealed to keep the down in place and prevent it from shifting around during use.

After filling the comforter, it is time to add any additional features or accessories. This might include a zippered closure to keep the filling in place, or decorative stitching or patterns to enhance the appearance of the comforter. These features can vary depending on the manufacturer and the specific model of comforter being produced.

Finally, the comforter is wrapped and packaged for distribution to retailers and customers. This involves careful packaging to protect the delicate down filling from damage during transportation. Once packed, the comforters are shipped to stores or directly to customers, ready for purchase and use.

In conclusion, the manufacturing process of down comforters involves a complex series of steps that require skill, expertise, and attention to detail. From gathering the down to adding final touches like decorative stitching, every step plays a crucial role in creating a high-quality product that delivers warmth and comfort. As consumers continue to demand more from their bedding products, manufacturers will need to remain committed to producing comfortable, durable, and stylish down comforters that meet their needs and expectations.

Articles related to the knowledge points of this article:

Title: The Numerous Advantages of Down Comforters: An In-Depth Analysis

Title: The Art of Properly Maintaining Your Down Comforter for Years to Come

Title: 天猫 Store Explores the World of Down Comforters: A Comprehensive Review

Ikea and Muji: A Comparison of Duvets

Dog Down Comforters: The Ultimate Solution for Your Furry Friends Sleep