Title: Zhengzhou Feather quilt Processing: A Comprehensive Guide

Zhengzhou Feather quilt Processing: A Comprehensive GuideZhengzhou feather quilt is a type of traditional Chinese handicraft that has been passed down for generations. It is known for its soft texture, delicate embroidery, and intricate designs. In this comprehensive guide, we will explore the process of making Zhengzhou feather quilts from start to finish.To begin, the fabric used in the quilt is carefully selected and cut into the appropriate size. The embroidery design is then traced onto the fabric using a pencil or pen. Once the design is complete, the threads are carefully chosen and tied to create the desired effect. The embroidery is then filled with feathers, which add both texture and beauty to the final product.After the embroidery is completed, the quilt is assembled by layering the different parts together until it forms a complete quilt. The edges of the quilt are then finished off with binding tape to ensure that they stay in place throughout use.Overall, Zhengzhou feather quilt processing requires skill, patience, and attention to detail. However, the end result is a beautiful and unique piece of art that can be enjoyed for many years to come. Whether you are an experienced artisan or just starting out, this comprehensive guide will provide you with all the information you need to create your own stunning Zhengzhou feather quilt.

Introduction

Zhengzhou, the capital city of Henan Province in central China, has a long history and rich cultural heritage. The city is famous for its textile industry, particularly its production of high-quality feather quilts. In this article, we will provide a comprehensive guide to Zhengzhou feather quilt processing, covering topics such as materials, production processes, quality control, market demand, and future trends.

Materials used in Zhengzhou Feather Quilt Processing

The production of feather quilts in Zhengzhou mainly involves the following materials:

1、Feathers: The primary raw material for feather quilts is goose or duck feathers. These feathers are sourced from local farms and are carefully selected based on their cleanliness, thickness, and density. The feathers are then cleaned, deboned, and sorted according to their size and quality.

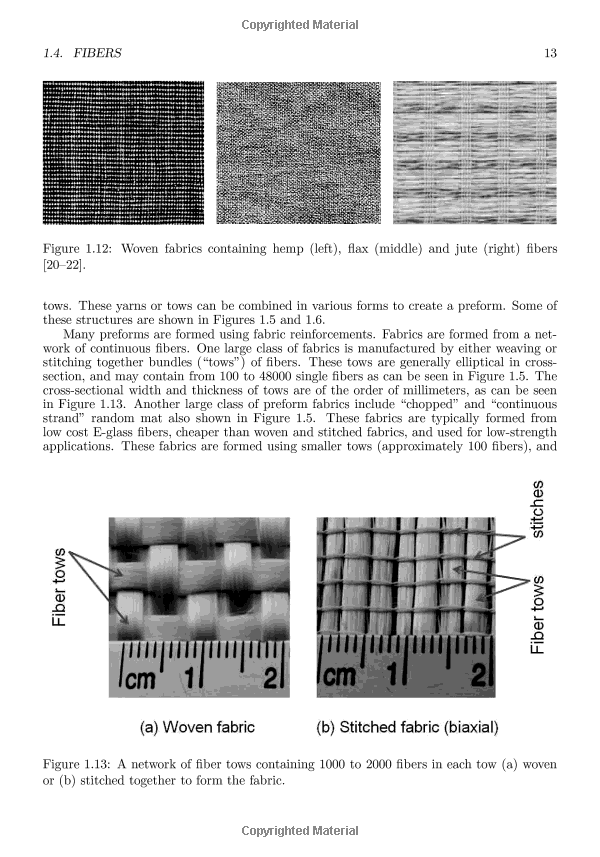

2、Fabric: The fabric used in feather quilts can be made from various materials such as cotton, polyester, and silk. Cotton and polyester fabrics are more commonly used due to their durability and easy maintenance properties. Silk fabrics add a luxurious feel to the quilt and are often used for special occasions.

3、Filling: The filling material for feather quilts can be either natural or synthetic. Natural filling materials include down and feather blends, while synthetic filling materials include foam and microfiber padding. Both natural and synthetic filling materials offer different levels of warmth and comfort, and the choice depends on the consumer's preferences and budget.

Production Processes in Zhengzhou Feather Quilt Processing

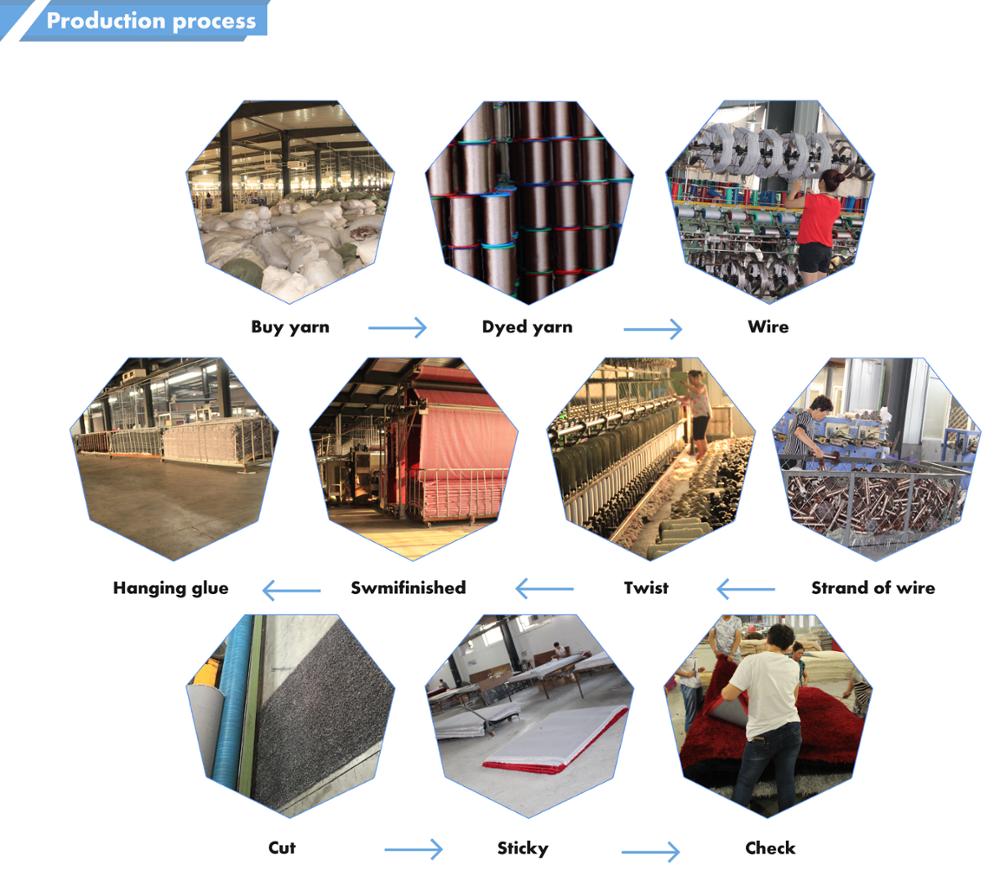

The production process for Zhengzhou feather quilts typically involves three main steps: cleaning, filling, and sewing.

1、Cleaning: The first step in making a feather quilt is to clean the feathers thoroughly. This involves beating the feathers with a brush to remove dirt, dust, and other impurities. The cleaned feathers are then sorted according to their size and quality before being deboned to make them easier to handle during the filling process.

2、Filling: Once the feathers have been cleaned and deboned, they are ready for filling. The filling process can be done manually or using machines depending on the scale of production. If using machines, the feathers are fed into a machine that fills them with a specific amount of stuffing (such as down or foam) until the desired thickness is achieved. The filled feathers are then compressed to remove any air pockets and ensure even distribution of stuffing throughout the quilt.

3、Sewing: After the filling process is complete, the quilt top is sewn together using a zigzag stitch or other appropriate sewing method. The stitching should be tight and even to prevent the filling from shifting or moving during use. Finally, the edges of the quilt are finished with binding or trim to enhance the overall appearance of the product.

Quality Control in Zhengzhou Feather Quilt Processing

Quality control is an essential aspect of Zhengzhou feather quilt processing. To ensure that each product meets the highest standards of quality, manufacturers follow several key steps:

1、Inspection: Before production begins, each batch of raw materials is inspected to ensure that they meet the required specifications for cleanliness, thickness, and density. During production, regular inspections are carried out to monitor the filling process and detect any issues early on.

2、Testing: Several tests are conducted on each finished product to assess its quality parameters such as warmth retention, softness, breathability, and water resistance. These tests help manufacturers identify any defects or inconsistencies in their products and take corrective action if necessary.

3、Packaging: Once the final product passes quality control checks, it is packaged securely to prevent any damage during transit. The packaging should also include clear labeling specifying the product name, material composition, care instructions, and any relevant certifications or awards.

Market Demand for Zhengzhou Feather Quilts in China and Abroad

Despite the increasing popularity of synthetic bedding options, traditional feather quilts continue to hold a special place in many households in China and around the world. This is due in part to their unique ability to regulate body temperature, providing a comfortable sleep environment regardless of external temperature changes. Additionally, feather quilts are known for their luxurious feel and timeless elegance, making them ideal for special occasions such as weddings, birthdays, and holiday celebrations.

In recent years, there has been growing demand for eco-friendly bedding options that offer similar comfort levels to traditional feather quilts but without the environmental impact of down feathers. As a result, many Zhengzhou feather quilt manufacturers have begun experimenting with alternative materials such as bamboo fiber or recycled polyester fibers to produce environmentally friendly products that still maintain the same level of comfort and quality as traditional feather quilts.

Future Trends in Zhengzhou Feather Quilt Processing

As consumers become increasingly aware of the environmental impact of traditional down products and seek more sustainable bedding options, there is likely to be continued growth in the market for eco-friendly feather quilts in China and abroad. Manufacturers in Zhengzhou who invest in research and development to create innovative new materials and production technologies may well be well positioned to capitalize on this trend over time. Additionally, advances in automation and artificial intelligence may enable manufacturers to streamline production processes further while maintaining high levels of quality control and customer satisfaction.

Articles related to the knowledge points of this article:

Title: The Undesirable properties of Down Comforters: A Guide to Better Sleep

Wuxi Down Comforter Recycling and Exchange Program